|

THREE

INTERDEPENDENT SERVO CONTROL SYSTEM |

|

|

One-servo for film feed drive |

|

|

One-servo for heat-sealer vertical drive and |

|

|

One-servo for catching drive |

|

Special Features |

|

300

Shots/min. Accurate registration, less waste |

|

Automatically

stop when running out of film |

|

Servo catching unit

provides outstanding bag stacking |

|

Automatically

stop when film feeding blocks or bags jam |

|

Sealing

Blade Driven by Servo Motor System

(With functions for setting sealing time) |

|

Automatically

stop when The temperature not reaching setting. |

|

Digital setup,

accurate registration, less waste |

|

Automatically

stop when the bags become super-imposed or overlapped |

|

Pleasant Cutting

and Sealing, with high firmness |

|

|

|

Imported high

speed conveyor belt for long service life. |

|

|

|

Convenient to change

for various bag shapes. |

|

|

|

Various unwinder and

rewinder to meet requirements. |

|

|

|

Ruggedly constructed

for maximum stability during high speed operations. |

|

|

|

Standard Specification

|

|

1.Fikm |

OPP, CPP HDPE, LLDPE, and other plastic film capable

being fusion sealed.

Film Thickness : 20 to 100 micron *1 |

|

2.Roll Size |

Maximum width : 1400 mm,

Maximum diameter : 600 mm |

|

3.Unwinding Unit |

Horizontal roll film shaft, Triangular plate system, Definitive

tension control system, powder brake equipment. LPC System |

|

4.Control System |

Numerical control system |

|

5.Film feeding Servo |

MITSUBISHI

Servo Pack |

|

6.Sealing Blade Servo |

MITSUBISHI

Servo Pack ,

(With functions for setting sealing time) |

|

7.Catching Servo |

MITSUBISHI

Servo Pack, |

|

8.Bag Making Capacity |

Maximum number of shots (HDPE#15) : 300 shots/min,(CCP#40) : 250

shots/min,

Maximum film speed : 40 m/min *3 |

|

9.Machine Size & Weight |

1.88m*5.92m*1.5m, 2800KG |

|

. |

|

|

Optional Accessories

|

|

Round hole punching device. |

|

Bag dividing device. |

|

Butterfly hole punching

device. |

|

Automatic hot melt

coater. |

|

Automatic product

outfeed conveyor. |

|

Ultrasonic longitudinal

sealing device. |

|

Edge positioning

controller (EPC). |

|

Zipper device |

|

Upper and lower line

heating device. |

|

Hem sealing device

|

|

Solid edge device

|

|

|

|

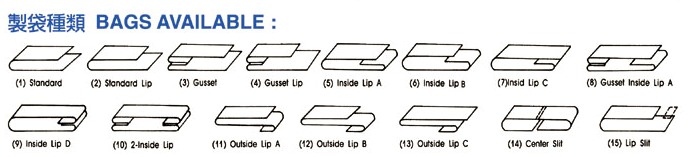

Application |

|

|

It's available for

general side sealing plastic bag, such as OPP bags, hanging Bags,

zipper bags, carry bags, book cover, Shirt bags etc.This machine

also available for special design. |

| Bag Making Sizes

& Shapes |

[ Standard Specifications ]

|

Half fold fusion bag making

- W (Bag width) : 70 to 500mm

- L (Bag length) :200 to 650mm

|

[ Using Optional Equipment ]

|

Double triangular plate system 2-line

bag making

- W (Bag width) : 70 to 500 mm

- L (Bag length) : 100 to 300 mm

|

|

Gusset 1-line bag making

- W (Bag width) : 70 to 500 mm

- L (Bag length) : 200 to 650 mm

- G (Gusset fold width) : 30 to 70 mm

|

|

|

|